Key Takeaways

- Biofabrication merges biology and technology to create sustainable materials.

- This innovation has the potential to revolutionize industries from fashion to construction.

- Advancements in biofabrication could lead to reduced environmental impact.

Introduction to Biofabrication

Biofabrication, a burgeoning field at the intersection of biology, engineering, and materials science, leverages biological processes to produce complex materials and structures. Unlike traditional manufacturing, which often relies on finite resources and energy-intensive processes, biofabrication employs living cells and biomaterials to generate sustainable alternatives. This innovation is poised to transform industries by introducing eco-friendly materials that mimic or even surpass the properties of their conventional counterparts. The ingenuity of biofabrication lies in its ability to utilize the natural growth and synthesis processes of living organisms, making it a key driver of the sustainable manufacturing revolution.

Newsletter

Never miss out on great articles — just enter your email and receive a weekly update!

Applications Across Industries

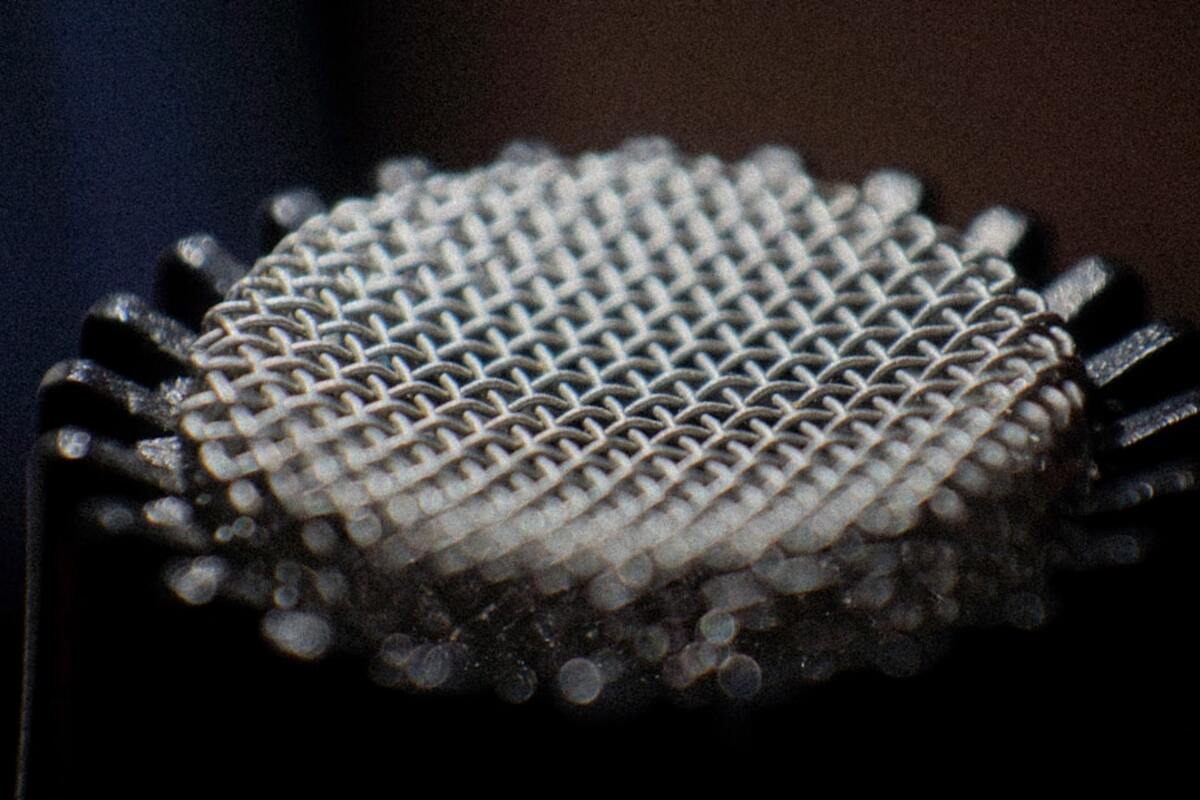

The applications of biofabrication are as diverse as they are promising. In the fashion industry, companies are exploring the use of biofabricated textiles derived from microbial fermentation or genetically engineered yeast. These textiles not only offer a sustainable alternative to traditional fibers but also open the door to new textures and functionalities. Similarly, in the construction sector, biofabricated materials such as mycelium-based bricks offer a biodegradable and energy-efficient alternative to traditional building materials. Their lightweight and insulating properties make them ideal for sustainable architecture. Furthermore, the medical field is witnessing breakthroughs with biofabrication techniques that enable the creation of patient-specific implants and tissue scaffolds, enhancing the effectiveness of regenerative therapies.

Future Prospects and Challenges

Despite its potential, biofabrication faces several challenges that must be addressed to realize its full impact. Scaling production processes to meet industrial demands while maintaining cost-effectiveness is a significant hurdle. Moreover, the integration of biofabricated materials into existing supply chains requires careful consideration of regulatory standards and consumer acceptance. However, advancements in synthetic biology and bioprinting technology are paving the way for overcoming these obstacles. As research and development in biofabrication continue to progress, the field holds promise for a future where materials are not only high-performing but also environmentally harmonious. In this future, the boundaries between the natural and the manufactured will blur, ushering in an era of innovation that is as sustainable as it is revolutionary.